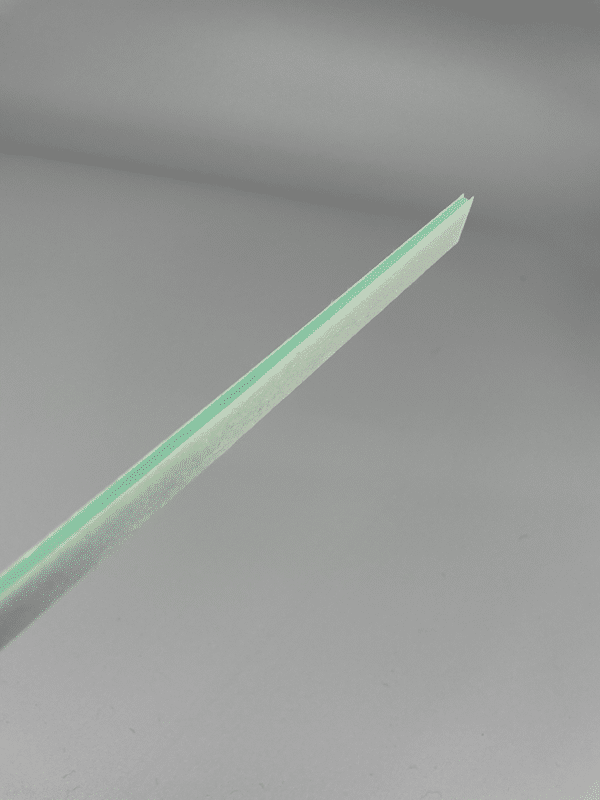

GRP PRODUCTS

Glass fibre reinforced plastic

GRP

Low weight

Our GRP profiles have the same strength as steel but only 1/4 the density; for aluminium this is about half. This allows for lightweight constructions, easy handling as well as cost-efficient transport.

Strength like steel

Compared to conventional materials, glass fibre reinforced plastic has a lower weight – only a quarter of the density. But weight savings can also be achieved as an alternative to aluminium, as our glass-fibre reinforced plastics have only two-thirds the density of aluminium.

Weight saving with GRP

The low weight of the GRP profiles means that significant weight savings can be achieved in the final solution, as slimmer and lighter constructions are possible that place fewer demands on the subsoil. A simpler solution also reduces construction costs, for example for special machinery and cranes.

Easy assembly by hand

Due to their low weight, the handling of the profiles is easier. Often the entire assembly is so light that manual handling is possible. This is why glass-fibre reinforced plastic is often the first choice when the assembly site is difficult to access or when assembly must be carried out quickly

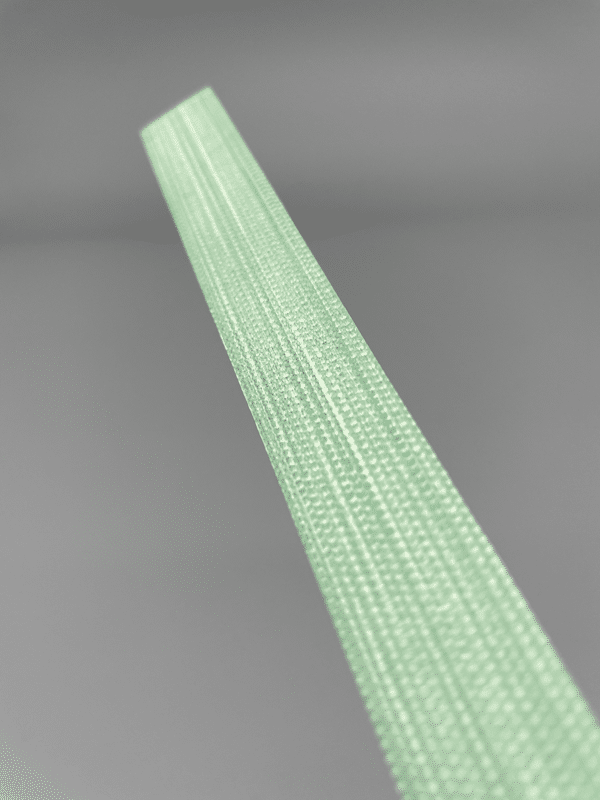

Glass fibre reinforced plastic

often also called glass-fibre reinforced plastic (GFRP), is a fibre-plastic composite made of a plastic and glass fibres. Thermosetting plastics (e.g. polyester resin [UP] or epoxy resin) as well as thermoplastic plastics (e.g. polyamide) come into question as a basis.

.

Properties and areas of application

Glass-fibre reinforced plastics are a cost-effective and yet very high-quality fibre-plastic composite. In applications subject to high mechanical stress, glass fibre-reinforced plastic is found exclusively as continuous fibres in fabrics or in UD tapes.

Compared to fibre-plastic composites made of other reinforcing fibres, glass fibre-reinforced plastic in combination with a suitable plastic matrix has high elongation at break, high elastic energy absorption, but a relatively low modulus of elasticity. Even in the fibre direction, it is lower than that of aluminium. It is therefore not suitable for components with high stiffness requirements, but it is good for leaf springs and similar components.

Glass fibre reinforced plastic has excellent corrosion behaviour even in aggressive environments. This makes it a suitable material for containers in plant construction or also for boat hulls. Since these hulls are also non-magnetic the material was used to build minesweepers as early as 1966.

.